ORLEN is advancing e-mobility with 10,000 charging points by 2030, pioneering renewables like offshore wind, and driving circular economy innovations.

ORLEN aims to build 10,000 charging points by 2030, kickstarting the road to reaching e-mobility goals.

ORLEN is a Central European energy company and leader in energy transition, focusing on a greener future.

The company’s sustainability strategy aims to minimise climate impact, protect the environment, ensure good working conditions, cooperate with local communities and manage responsibly.

ORLEN’s climate goals

ORLEN is determined to design and build Poland’s first offshore wind farm, further solidifying the future in green energy.

The company has reached the Final Investment Decision (FID) to build Baltic Power, the first offshore wind farm in Poland.

The project, set to enhance Poland’s energy system through the addition of nearly 1.2 GW in 2026, will be pursued in partnership with Canada’s Northland Power.

Baltic Power will deliver sustainable, accessible energy to an estimated 1.5 million households.

Not only focusing on wind power, the company is set on many other sustainable targets and projects.

Key sustainability targets and initiatives include:

- Achieve carbon neutrality by 2050

- Reduce emissions in refining, petrochemical and upstream segments by 25% by 2030 (vs 2019 levels)

- Cut carbon intensity in the energy segment by 40% by 2030

- Reduce net carbon intensity for total energy sold by 15% by 2030

- Implement a circular economy, including the Blue Bridge project to reduce water usage from the Vistula River by 25%

- Construct a waste incineration facility for hazardous medical and veterinary waste

- Convert 40 hectares of industrial land in Warsaw to green space by 2025

- Reduce water usage at car washes by 30-60% and chemicals by 20% by 2030.

Renewable energy and alternative fuels

ORLEN Południe, a member of the ORLEN Group, has signed a contract for the construction in Trzebinia of a UCO FAME plant which will convert used cooking oils and animal fats into 30,000 tonnes of second generation esters and 7,000 tonnes of technical grade glycerine annually.

Daniel Obajtek, President of the PKN ORLEN Management Board comments: “The UCO FAME plant will increase the supply of alternative second-generation biocomponents, with a benefit to the natural environment.

“This innovative solution will allow us to expand our portfolio by adding another environmentally friendly product, and ORLEN Południe – to continue developing advanced know-how in biotechnology. Importantly, the project is also in line with the EU’s Renewable Energy Directive II, which promotes the processing and reuse of waste products.”

ORLEN also aims to become the leader in e-mobility in Poland and the Czech Republic by 2030 also taking a strong position in Germany – the strategy begins with building 10,000 charging points by 2030.

The company supports the decarbonisation of transport through hydrogen, a fuel that can be particularly useful in urban, long-distance, and rail transport applications.

With its hydrogen strategy, ORLEN plans to be at the forefront of hydrogen mobility in Central Europe by 2030, producing 19 thousand tonnes of automotive-grade hydrogen.

Hydrogen will become more accessible as the hydrogen refuelling network is expanded to 100 service stations in Poland, the Czech Republic and Slovakia.

ORLEN aims to strengthen its regional leadership in alternative fuels by implementing significant investments in the production of biofuels, including: Hydrotreated vegetable oils (HVO), co-HVO,used cooking oil methyl ester (UCOME), lignocellulosic bioethanol, biogas and biomethane.

By 2030, these investments will enable ORLEN to increase biofuels production to about 1 million tons per year, thus reducing the carbon footprint of its fuels.

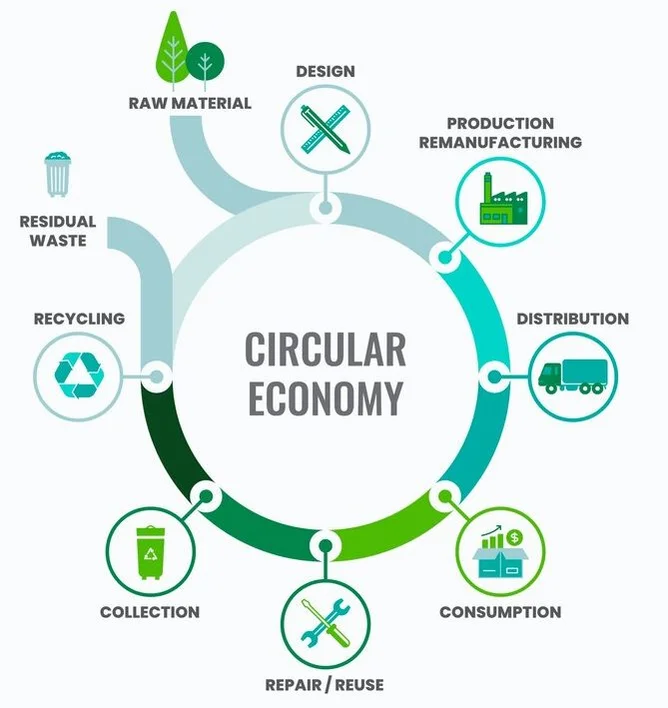

ORLEN’s circularity strategy

Whilst ORLEN understands the importance of biofuels, it also acknowledges the need for a circular economy.

As product owners, companies will be responsible for their products from design to final disposal, the obligation to recycle now falls on the producer and the consumer.

Product-as-a-Service (PaaS) facilitates recycling and fits into the circular economy model, whilst lowering the cost of satisfying needs.

Instead of buying durable goods, ORLEN pays to use them with the support of digital tools, adding to their lack-of-waste target – a tip for many companies.

By 2030, the company has an annual recycling capacity of up to 400,000 tonnes, enabling the opportunity to generate new petrochemical products.

Daniel adds: “We are committed to developing our business in a sustainable way, recognising the growing importance of latest technologies in building competitive advantage.”

ORLEN is integrating these sustainability goals into their business strategy and management systems to build long-term value for stakeholders while supporting energy transition in Central Europe.

The aim being to become a regional leader in sustainability and a regular issuer of green bonds.