ABB reduces industrial electronic waste to landfill by 93% in four years as part of its circularity programme.

The increasing consumption of electric devices in the industrial sector is a growing global concern, with approximately 62 million tons of electronic waste generated globally.

Estimated to rise to 82 million tons in 2030 according to UNITAR, the impact of industrial electronic waste on the environment can include resource waste, carbon emissions and soil and water contamination.

The key challenges include:

- Complexity of recycling

- Hazardous materials

- Data security risks

- Limited recycling infrastructure

- Lack of standardised disposal protocols

- Energy consumption and costs

“Collaboration with suppliers and partners is essential for circularity-driven innovation. Each of us has a distinct role to play in transitioning to a fully circular economy. By preventing resource waste and reusing materials, we protect the environment and ensure resources for future generations. Let’s move away from linear systems and work together to build sustainable models.” – Anke Hampel, ABB Head of Sustainability.

ABB Energy Industries Service and its recycling partners

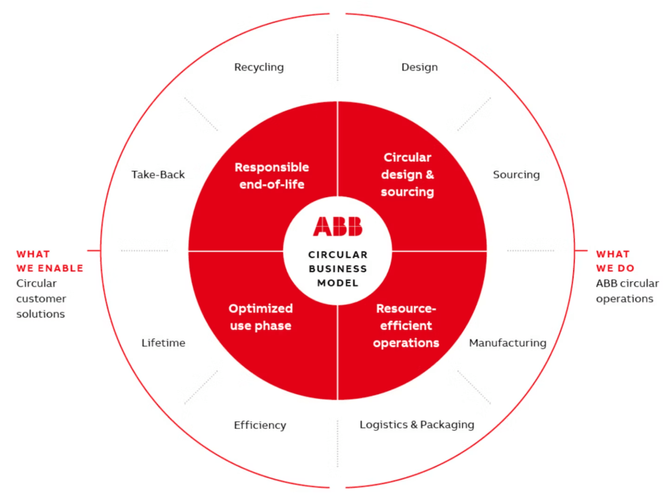

Focused on preserving resources at every stage of a product’s lifecycle including responsible end-of-life services, ABB sustainability and business models are based on circularity.

This approach aims to minimise waste and maximise resource efficiency by recycling, reusing, and regenerating resources.

Moving beyond the wasteful linear model of ‘take-make-dispose’, ABB is embracing ‘reduce-reuse-recycle’. By valuing waste as a resource, ABB reduces its dependence on virgin materials, lowers its emissions, and restores its ecosystems.

“End-to-end traceability and extending the lifecycle of our products is crucial, especially in the face of a rising global demand for critical materials. Without the transformation of production and consumption models to support the circular economy, we cannot meaningfully preserve natural resources and cut emissions,” says Marie-Hélène Westholm-Knebel, Global Head of Sustainability at ABB Energy Industries.

“Our collaborations with recycling partners ensure that sustainability standards are upheld from the very beginning to the final stage of a product’s lifecycle.”

ABB reduces its industrial electronic waste to landfill

Over the last four years, ABB Energy Industries Service and its recycling partners have reduced the industrial electronic waste sent to landfills by 93% since the launch of its Parts Circularity Program.

Of 32,000 faulty items processed across the four years, 214.5 kg went to landfill in 2020 but by the end of 2023, this had fallen to 14.2 kg.

Focusing on repair, reuse and recycling to extend the life of faulty parts, reduce waste and conserve resources, ABB’s programme aims to combat the amount of industrial electronic scrap that is sent to landfills.

By collaborating with Stena Recycling in Europe and Ohio Drop Off in the US to provide certified reports that assess the material properties of each part across various categories, ABB offers transparency in sustainability reporting.

ABB also offers financial incentives for customers to exchange faulty parts for remanufactured or refurbished ones providing a cost-effective and sustainable solution to reduce waste.

When parts can’t be repaired or used for remanufacturing, ABB responsibly disposes of the waste, allowing customers to recover valuable materials and reduce reliance on virgin resources. In some cases, parts are disassembled, cleaned, inspected, reconditioned and reassembled to create remanufactured parts.

“The success of this programme has already been proven at industrial plants around the world where our customers have service agreements that enable them to play an active role in striving for a circular economy,” says Paul Sundt, Service Segment Manager at ABB Energy Industries.

“We hope to see this continue as more customers realise the value, and improved sustainability, that can be generated across their supply chain.”